"Patent Pages"

by Ray Klingensmith

Reprinted from "INSULATORS - Crown Jewels of the Wire", August 1979, page 11

The October 15, 1872, Oakman Patent

The name Samuel Oakman probably

brings to mind a longer and more interesting insulator involvement than does any

other name to the insulator collector. Oakman was probably involved with the

production and invention of insulators longer than any other person in the

industry. He was associated with glass manufacturing, or the patenting of

insulators in the late 1860's, and perhaps earlier, thru the early 1900's. Many

inventions are credited to him, and his impact on the Boston area insulator

manufacturing was great. He had many patents, among them the October 15, 1872,

patents for a method of forming a screw thread on the inside of glass

insulators.

The "segmented thread" is a very familiar characteristic

of the Boston Bottle Works insulators to the collectors of today. These

insulators are found in a wide variety of styles and colors. The

"Bostons" have always gathered a large amount of interest, due to

their unique characteristics and scarcity. Most collectors rank them as one of

the more unusual and desirable items to add to their collection.

On October 15,

1872, Samuel Oakman, of Boston, Massachusetts, was granted two patents for

improvements in formers for segmentally screw-threaded insulators. The device

used may at first seem complicated (see complete patent copies), but after close

examination they can be easily understood. There were two separate patents, one

for four segment threads, and one for three segment threads. What the inventions

amounted to was a method of producing the threads in the glass in an easier and

quicker manner. I personally don't feel that Oakman had any ideas in mind for

any benefits from the segmented threads while the insulator was in use (as far

as insulation properties were concerned); it simply was an easier way of

manufacturing them, saving production time and, perhaps, production costs.

What

the invention consisted of in case A (#132,214) was a tubular plunger with four

equally spaced slots. Within each of these four slots was held a threaded

segment. This complete plunger was inserted into a mold containing molten glass.

After a short period of time, the interior bolt could be turned, which would

rotate the threaded segments one-quarter turn, that would place them inside the

tube, and expose a slotted portion next to the threads molded in the insulator.

In case B (#132,215) the product is somewhat similar in the result, but the

method of forming the threads is different. This one has a tubular plunger with

three slots. Within each of these slots is a threaded segment. The inner

portions of these segments (toward the very center of the plunger) are grooved

in a manner to grasp a shaft which runs vertically in the center of the plunger.

This shaft is tapered from a wide width at the top, to a narrower width at the

bottom. After the plunger remained in a mold containing molten glass for a

period of time, the inner shaft was drawn upward. The segments were attached to

this shaft, and due to the shaft becoming narrower as it was raised, the

segments would be drawn inward to a point, where, when the entire plunger was

raised, the segments would clear the threads formed in the insulator. Traces of

this method are evident in the three-segmented "Bostons". At the top

of the pinhole lines can be seen extending from the segmented threads toward the

center.

In the previous written material, I've

referred to the insulators made under the October 1872 patent process as

"Bostons". This is because some of the insulators made under that

process are embossed "Boston Bottle Works". However, all of the

insulators made with those threads may not have been made at Boston Bottle

Works, which I will explain as the story goes along.

The Boston Bottle Works was

listed in the Boston City Directory for the years 1872 thru 1877 as

"manufacturers of green, black, and amber glass ware; carboys, demijohns,

fruit jars, druggists' ware &c." (See copies of ads below.) Actual

production of wares may have taken place earlier than 1872. It seems to me that

perhaps the company was in business for some time prior to their listing in the

directory. Perhaps they were in operation as early as 1871 and were entered in

the directory for the next year.

1872 Boston City Directory ad.

Ad from the Boston City Directory, 1873-1877.

More than likely, the first embossed

segment threaded insulators made at Boston Bottle Works were those marked with

"Patent Applied For", or "Patent Apld For". One can assume

the patent referred to in those embossings was for the segment threaded idea;

but it could have been for another feature. Insulators with both the Boston

Bottle Works and Patent Applied For embossing are found in four styles, these

being the following C.D. numbers: 145.6, 158, 158.2 and 158.9. Once again, it's

easy to assume that the above mentioned insulators were the first made under

Oakman's "segment" invention. However, there are some insulators (CD

136.4 and 158.2) with four segment threads which are unembossed. Were these,

perhaps, made by, or for, Oakman prior to his patent application? They could

have been made after 1877 and the existence of Boston Bottle Works. Maybe Oakman

made them while associated with another glass company at a later date. It seems

to me an earlier production date for these would be more likely. Still another

possibility would be a separate firm producing them without any ties to Oakman

at all -- a competitor in the industry.

Next we come to those insulators marked

with both Boston Bottle Works and the October 15, 1872, date. These, perhaps,

are the easiest to date. Most likely they were made between October 1872 and

1877. (The ones marked Patent Applied For could also have been made during this

same time period, as the plunger with that embossing could have been used for

several years, even though the patent was granted.) There are four styles found

with the B.B.W. and 1872 date embossings. They are found in the following C.D.

numbers: 127.6, 143.6, 158.2 and an insulator like the 158.2 without an inner

skirt (six sided dome).

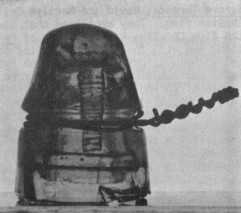

There is also an insulator embossed "Chester 104

Centre St. N.Y. Patented" that has four segment threads. The embossing is

found at the base of the inner skirt on this item, as is the case with most

Boston Bottle Works items. Chester was a telegraph supply house in New York City

from the mid 1850's to the 1870's and perhaps later. These insulators could have

been made for Chester by Boston Bottle Works.

|

|

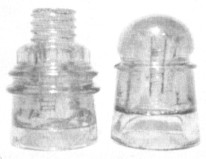

Tom Moulton photo

Insulator

embossed Chester 104 Centre St. N.Y.

Patented.

Fig. 1 |

Tom Moulton photo

Insulator similar to CD 136.7 with an inner skirt.

Fig. 2 |

They could have been made by

Oakman at a glass house after the existence of B.B.W.; or perhaps

Chester had them made by a manufacturer separate from both Oakman and B.B.W.,

which is doubtful. This particular insulator is presently listed as a C.D. 158,

although it is somewhat different than other C.D. 158's. The dome is shaped

somewhat different, and the wire groove does not circle the insulator in a

straight line as with other 158's. Instead, it travels in more of what

collectors call a wavy pattern (see photos in figs. 1 and 2).

Next we come to

those insulators marked with just the 1872 date and no reference to Boston

Bottle Works. I saved this embossing for last because I personally feel these

were made after the existence of Boston Bottle Works. Oakman was listed as

"agent" for the Bay State Glass Works for 1878 and 1879. The salesroom

for Bay State was at 97 State St., Boston (the same as for Boston Bottle Works

from 1873-1877). The plant was at 223 Bridge St., East Cambridge. I feel those

insulators marked "Pat Oct. 15, 1872" were made at Bay State in 1878

and 1879, or perhaps even later, by Oakman at even another glass factory. As

mentioned earlier, Oakman was very involved in either manufacturing or patenting

items as early as the late 1860's thru the 1900's. I would guess in any given

year in the 35-40 year span, you would find him associated in some way with the

manufacture of glass ware. After his association with Bay State in 1879, I'd

guess he continued the production of insulators with the segmented threads in

1880 and perhaps later, until he invented another improvement in forming threads

in insulators. This is referring to his September 9, 1884, patent, which was for

a collapsible plunger which formed a fully threaded insulator (that type of

threads found in the American Insulator Company insulators).

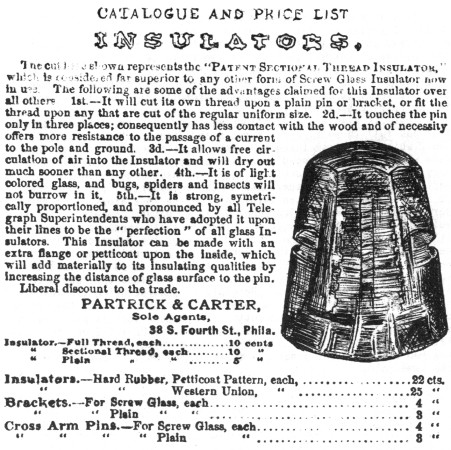

Evidence to my

feelings of Oakman making segment thread insulators after the existence of B.B.W.

is shown in the page from an 1880 Patrick & Carter Company catalogue on the

following page. The ad states that these could be made with what we term an

"inner skirt". That indicates they had someone (probably Oakman) still

making them. The ad suggests Patrick & Carter was not selling "old

stock" that had been produced a few years earlier, but were offering items

which could be produced as the customer specified. Note in the catalogue page

that Patrick & Carter are from Philadelphia. In their book, Before

Threads,

David and Marilyn Delling gave a brief history of the Chester firm. They

mentioned that Stephen Chester was a partner in the firm Chester, Patrick &

Co. of Philadelphia. With that information, and with the Patrick & Carter

page, the wheels started turning, and it brings forth perhaps a link between

Oakman and Chester and later Patrick & Carter. One can't be certain that

Patrick & Carter was an offspring of Chester, Patrick & Co.; but I am

assuming that Chester was associated with Chester, Patrick & Co. in the

early to mid 1870's. Then later, perhaps in the late 1870's, he withdrew his

interest in the company, and it became Patrick & Carter. At any rate, what

all the above means is that the C.D. 158 Chester could have been made by Oakman,

either at Boston Bottle Works (which I believe to be the case), or perhaps at

Bay State. Stephen Chester (brother of Charles in New York), while in

Philadelphia, offered the same line of material as the Chester firm in New York.

With Stephen's association in Philadelphia, the segmented insulators may have

later been offered there because of his earlier influence. (He could also have

been still associated with Patrick & Carter in 1880, even though he isn't

mentioned, but that's doubtful.)

Page from 1880 Patrick & Carter

catalogue. The insulator offered most likely was the C.D. 136.7 with 1872 patent

date, with three segment threads.

|

|

|

Bob Pierce photo

Insulator similar to CD 136.7

with inner skirt as described in above ad. Fig. 3 |

Bob Pierce photo

Base view of

fig. 3 showing inner skirt.

Fig. 4 |

Tom Moulton photo The CD 136.7

Fig. 5 |

It's interesting that in the printed material shown with the Patrick &

Carter insulator, mention is made that "it will cut it's own thread on a

plain pin or bracket, it offers more resistance to the passage of current

(because of the three segment threads), it allows free circulation of air into

the insulators". All three claims were probably not a factor in Oakman's

mind when he made the invention. It seems to me this was just a promotional

claim for advertising by Patrick & Carter.

There is also an interesting

insulator with the 1872 embossing that has full threads. (See figs. 6 and 7 for

photos of the C.D. 156.2 which has these threads.) This is very unusual in that

the date was for the segmented threading process. These insulators are very

scarce. I would guess these were perhaps made by Oakman in the early 1880's. The

threads found in these insulators are identical to those found in American

Insulator Company insulators. The threads were formed by Oakman's September 9,

1884, patent process. This involved a collapsible plunger which made a fully

threaded insulator. It's my belief that Oakman produced the C.D. 156.2

immediately after he thought of the collapsible plunger (prior to patenting that

idea). Perhaps he embossed the 1872 date on them so that in the event that

someone else saw the new method of forming threads, they would believe the idea

was patented. Possibly in manufacturing the insulators, the only mold he had to

form the inner skirt on was the one he used in making the segmented units. The

latter idea is probably the most likely to have happened. I don't own a C.D.

156.2 or the insulator similar to C.D. 136.7 with the inner skirt, so I can't

compare the two to see if the inner skirt was formed on both insulators by the

same mold.

|

|

John McDougald photo

The CD 156.2. Notice the

threads stop before going to the top of the pin hole, similar to the Am.

Ins. Co. threads.

Fig. 6 |

John McDougald photo

Base view of the CD 156.2 showing the

1872 embossing on the base of the inner skirt.

Fig. 7 |

What we term as "Bostons", those

insulators mentioned above, including the ones not embossed Boston Bottle Works,

have been found in a very wide spread area. Some types seem to be from only one

area, while others were used in various places. Probably the most commonly found

"Boston" is the C.D. 158. This particular insulator comes with two

different widths of wire grooves. The wide groove measures 1/2 inch high, and

the narrow groove approximately 5/16 inch. Both seem to have been used in the

same locations, primarily along the railroads in New York State. Joe Maurath

reports that the report is the only one of any Bostons being used in

Massachusetts. In a recent phone conversation with Fred Griffin, I learned much

about the use of Bostons in the South, and I hope my notes are accurate on

what Fred mentioned. Fred stated that perhaps a couple dozen 158's were found in

a river that separates Florida and Georgia. These were both the narrow and wide

groove variants. The 158 has also been found in small numbers in various

locations in New England. After the C.D. 158, it would be hard to place the

Bostons in order of rarity, as there are many scarce ones.

Besides the

segmented threads found in these insulators, there are many other unusual

factors about them. The six-sided dome which is found on many of them is a

unique characteristic. The hex dome could have been for a better grip for the

lineman to turn the insulator on the pin, or, more likely, it could have been

designed to receive a wooden wrench, to help turn the insulator on the pin.

The wooden wrench theory becomes more acceptable when looking at the

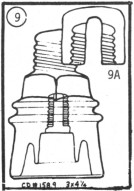

"screw-top" Boston (see fig. 8 for a photo of the C.D. 158.9). The six

sided portion of the C.D. 158.9 is of a smaller area than the "signal

type" Bostons, and it looks more like a design made to fit a wrench. The

158.9 also has the interesting "screw-top". This unusual design

could have been made for some other reason, but I think Joe Maurath has come up

with the right idea. Joe states: "I estimate these were used with a cap

with a slot extending up into each side (see fig. 9A). Possibly, the wire was

held up inside the cap's slots while the insulator was screwed down onto the

pin, so that the stationary cap was screwed onto the insulator's top, with the

wire in place, needing no tie wire. This could have been achieved because the

crown's threading spirals opposite than the pin's."

|

|

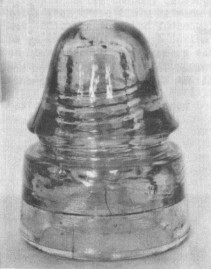

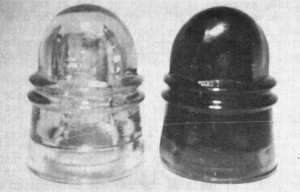

Cecil Boos photo

The screwtop Boston and the CD 143.6 with three segment threads.

Fig. 8 |

Joe Maurath

drawing showing the screwtop Boston and the cap ex plained in his theory.

Figs. 9 & 9A |

Joe continues: "To my knowledge, nobody has found

such a cap for the insulator's top. I'd imagine it would be very difficult to

find one, or at least a piece of one. If there was a cap, it was most likely a

cheap non-conductor of electricity like wood or glass. If it was glass, the

glass-to-glass contact would eventually break the cap; and if it was wood, the

same line conditions and the aging wood would eventually break the cap, dropping

the line."

Joe's theory seems very likely to be correct. The cap used on

these, if made of wood, would soon decay in the ground and would stand a very

slim chance of being in any condition to be found today. These insulators could

have been originally intended to be sold with caps, but after being produced and

maybe not being sold, perhaps they were later sold at a reduced price without

caps to be used as regular insulators. Does anyone own a C.D. 158.9 with wire

abrasions at the top of the screwtop?

The screwtop Boston has been found

primarily in the Augusta, Georgia, area, according to Fred Griffin. They also

have showed up in Alabama and Florida. Mr. Milholland, in a letter written to me

several years ago, made mention that divers had found them in the Indian River

in Florida. Fred Griffin mentioned an amber C.D. 158.9 that has been said to be

from Alabama, may have originally been located in Mississippi. Fred also

mentioned the dark green screwtop (if my notes are correct) was found in

Florida, and that some of the screwtops have threads on the top that appear like

they were "applied", something similar to the characteristic found in

American Insulator Company items. (This is referring to the creases found at the

bottom of the threads on the Americans, from the method of forming the threads

separately from the insulator and then "applying" them to it.) This

one also has an embossed triangle at the very top of the insulator. The C.D.

158.9 also comes in at least two height variations. Some have a screwtop with

four "threads", and some with six.

As far as color is concerned on the

Bostons, two things can be said: the colored ones are rare and beautiful! The

colored ones found so far seem to all have a color of their own, that is, there

is no other company that produced the exact color, and they are few and far

between. Probably the color found more often than the others (excluding the

aquas, of course) is the dark green. This is found primarily in the C.D. 158.2.

It is usually referred to as "emerald" green, but it has its own

unique color. The ambers are all very rare! Once again, I'd guess there are

probably more C.D. 158.2's in this color in collections today than of any other

C.D. number. I presently know of only one amber screwtop, one C.D. 145.6, and

two C.D. 158. The C.D. 145.6 is also known in a deep olive green. This is the

only C.D. number I know of in this color. The C.D. 136.7, which may have been a

later product, lacks any real deep colors. Most colored ones are of a lighter

shade, those being a light lime green, and a light lime green full of tiny

bubbles. There is one exception, however. One is known in a darker shade of

apple green. It is a darker shade, but is not the real deep color found in the

above mentioned items, which brings to mind the idea the reason for the lighter

color found in these perhaps could be due to the fact that they were advertised

(by Patrick & Carter) as follows: "It is light colored glass, and bugs,

spiders, and insects will not burrow into it. The unembossed C.D. 136.4, with

segment threads, which is most likely an Oakman product, is found in at least

four different shades of green. There also are some fully threaded C.D. 136.4 in

various colors with full threads, but, due to the fact that they did not have

segmented threads or were not embossed with the 1872 date, they have been

excluded from this article.

|

|

Bob Pierce photo

The amber

CD 158.

Fig. 10 |

Bob Pierce photo

The amber CD 145.6.

Fig. 11 |

|

|

Bob Pierce photo

The deep green CD

158.2 with dome embossing.

Fig. 12 |

John McDougald photo

The dark apple green CD

136.7 with 1872 patent date.

Fig. 13 |

It is interesting to note that all

the ambers, the olive green and some of the dark green, are found without the

patent date, but with "Patent Applied For". It indicates that most of

the colored glass was probably used in the earlier production. This is assuming

that those marked Patent Applied For were actually produced before the granting

of the patent on October 15, 1872. The ads which appeared in the Boston City

Directories throughout Boston Bottle Works existence clearly stated that green,

black and amber glassware was made; so in that respect it is rather surprising

that more insulators have not been found in those colors.

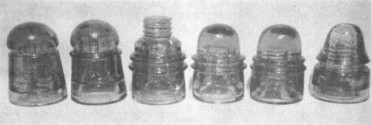

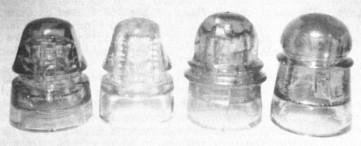

Cecil Boos photo

A

nice group of Bostons, including some of the rarer items.

Fig. 14

Cecil Boos

photo

The "Boston Signals", including the Chester, third from the

right.

Fig. 15

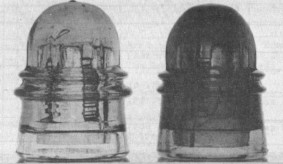

Cecil Boos photo

The "Boston Barrels". Green dome

embossed and green inner

skirt embossed, 2nd and 3rd from left. Amber, 5th from

left.

Fig. 16

|

|

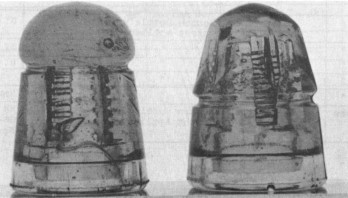

Cecil Boos photo

The CD 143.6 and 145.6.

Fig. 17 |

Cecil Boos

photo

Base view of the amber "barrel", showing the four segment

threads and embossing.

Fig. 18 |

Tom Moulton photo

On left, the aqua

"barrel" embossed on inner skirt: Boston Bottle Works - PATENT OCT.15.

72-. On right, the green variant, embossed on inner skirt: Boston Bottle Works -

PATENT APLD FOR-. Note how the lower wire ridge projects further out than the

top one on the aqua, and on the green one both ridges are nearly the same.

Fig.

19

Tom Moulton photo

On left, a blue-aqua CD 145.6 which was found on the New

York Central Railroad, embossed: Boston Bottle Works - PATENT APPLIED FOR-. On

the right, the "narrow groove" CD 158 which was widely used in New

York State, mainly on railroads.

Fig. 20

Abbreviations used in the checklist are as follows:

| bl-aq |

blue aqua |

lt lm |

light

lime |

in skt |

inner skirt |

| lt yl |

light yellow |

bbl |

bubbly |

NE |

North East |

| dk ol |

dark

olive |

lt gr |

light green |

NW |

North West |

| dk em |

dark emerald |

gr-aq |

green aqua |

E |

East |

|

ap grn |

apple green |

|

|

in shldr |

Inner shoulder |

In the checklist are variants which I

have either seen or have had reported to me. Some of the material pertaining to

the location of where found, embossing, etc. is incomplete, so if anyone has any

additional info, please let me hear from you. Following are additional comments:

#5-7 One of these was found in the west -- not sure exactly which shade of green

it was.

#10 This item is most likely what Patrick & Carter advertised in

1880.

#11 I have seen this item and would call it a darker shade of apple green.

Unlike any other Boston color.

#12 The bubbly light lime green one is very

similar to the one listed as light lime green (#13), except that this one is

full of tiny bubbles. Both colors are very light.

#14 This insulator has the

same lettering as #10-13, with the exception that it's arced in the opposite

direction (at the bottom of the inner skirt when reading the lettering, rather

than at the top). Also it is a larger, script lettering.

#15 This insulator is

unusual in that it is three segmented and has an inner skirt. I believe this is

the same style as the C.D. 136.7 (same mold). The C.D. 158 has either a

5/16" or 1/2" wire groove. The 136.7 has a 3/8" wire groove, and

the dome is squattier looking, and that is the way this item is also. So rather

than having a regular C.D. 158, I believe this to be what normally would be a

136.7, only it has the inner skirt. This could be the insulator advertised by

Patrick & Carter as being available with an inner skirt.

#17 This insulator

is identical to the C.D. 143.6, except that it has an inner skirt. The one

specimen I viewed may have been intended to have an embossing at the base of the

inner skirt; however, due to what could have been an underpour, there was no

embossing.

#18 Could this be the same mold used for the C.D. 127.6, only with a

different plunger used with an inner skirt?

#20 This item was owned by a dealer

from Michigan many years ago. Due to the fact that #21 turned up in an antique

shop in Michigan also, I thought that perhaps both items may have been used on a

line in that state. I'll contact the former owner to see where the amber one was

originally located. (To my knowledge, both #20 and #21 are one of a kind.)

#22

This is the "American Boston", called such because of its American

Insulator Company style threads and the date found on many Boston Bottle Works

items. One of these was reported as having an embossing where the 15 was

embossed over a 12. Please advise if all are that way.

#23 Some of these may

exist without an embossing, due to an underpour. However, collectors have

reported they do exist unembossed with a fully poured inner skirt.

#24

Note that the C.D. 158 come in both a narrow and a wide wire groove. The exact

colors found in the 158's used on Cape Cod and also in the river between Georgia

and Florida were not known, so I did not include them in the listing of

"where found". But please note that they were found in those

locations.

#32-33 Made for the Chester firm which existed in New York City. One

of these was dug in St. Louis, Missouri. All others I've heard of came from the

U&D RR in Delaware County, New York. It has been reported by many collectors

that they were from the O&W RR (actually, the correct name is NYO&W) in

the same area. I believe these collectors to be in error, unless the U&D was

at one time a part of the O&W. I have talked with a collector in that area,

and they were used on the U&D. So, until someone can confirm their use on

the O&W, I'll omit it as a location where these were used. Also worthy of

mention is the fact that the dome is shaped differently than the regular C.D.

158, as there is a cutout or slot at the very top of the wire groove on three of

the six sides of the dome, and the wire groove is "wavy" rather than

straight. This insulator, interestingly enough, is formed in a three piece mold

(lines over dome), most likely made that way due to the shape of the wire

groove.

#38 Four of these were reported. Without seeing all four together, it is

difficult to say if they are all the same shade of amber. One was dug in the

Sidney, New York, area several years ago. It was believed to have been used on

an old cross country telegraph line, rather than along a railroad. Two others

came from an area some distance further southeast in New York State.

#41 This

embossing circles the top of the dome, and is usually rather weak. One was

reported with a backward "n" in the word "patented". All of

these may or may not be embossed with the error. Please advise.

#45 Some of

these have traces of embossing on the dome. The dome embossing referred to above

could have been attempted to be blocked out, and not all the letters removed?

#46 This item is shaped like C.D. 158.2, only it has no inner skirt. Also it has

three segment threads. The embossing reads: "PAT" or

"PATENT", not sure which. Found in San Francisco.

#47 This one is

embossed with "PAT". Almost certain it was found in the West.

#50

Embossed triangle on top of screwtop.

#51 Only one known at present. This is

about the same color found in the C.D. 158.2, except that, I believe, it is a

darker shade.

#52 Saving the best for last! This one probably would gather more

attention than any of the other 51 items described. Several collectors have

mentioned this one to me, and most refer to it as being from Alabama. One

collector stated it is believed to have originally been located in Mississippi,

and I would guess that to be correct, as the collector said the information came

from a knowledgeable source.

Cecil Boos photo

The three segmented family.

Fig. 21

Cecil Boos photo

The aqua and amber barrels.

Fig. 22

Well, finally,

after days of writing, the article is at its end. There is probably more

information which I will realize I forgot once I send this to Dora, but I'm long

overdue in getting it to her now. This article was put together with a great

deal of help from many, many thoughtful friends. I'll try to list all those who

helped out in some way, and hope I don't forget anyone, there were so many.

For

sending very long detailed lists of many items in their large collections,

thanks to Cecil Boos, Tom Moulton and Bob Pierce; to Joe Maurath for the

"Boston ads", drawings, and quotes from his material; to Cecil Boos,

John McDougald, Tom Moulton and Bob Pierce for many fine photos; the Branhams

for patent copies; and for other help and information, Dave and Marilyn Delling,

Gerald and Esta Brown, Ron Gavin, Fred Griffin, John Hewitt, Kevin Lawless, Edna

McDonald, Bill Motisher, Larry Richards, Ed Wood and N. R. Woodward.

|